Gaskets

A broad range of gaskets made from all types of materials. Our gaskets provide the optimal seal in preventing water, salt, sand, and dust from entering the wind turbine.

A wide range of sealing solutions designed to provide optimal sealing in wind turbines

The performance of a wind turbine depends on the combined performance and reliability of all components in the construction.

Whether you are a manufacturer, supplier, or any other stakeholder in the wind turbine industry, you have much to gain from always using optimal sealing solutions.

Benefit from durable sealings that can withstand harsh conditions.

With DAFA’s solutions, such as gaskets, profiles, and sealing strips, you can protect wind turbines from the ingress of water, sand, salt, and dust, and prevent oil leakages.

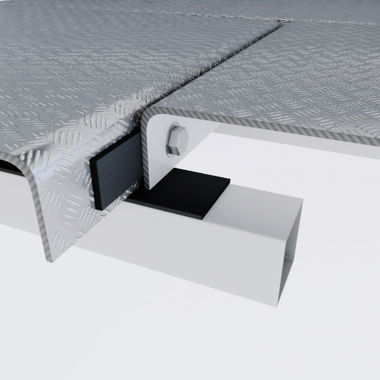

Sealing with strips

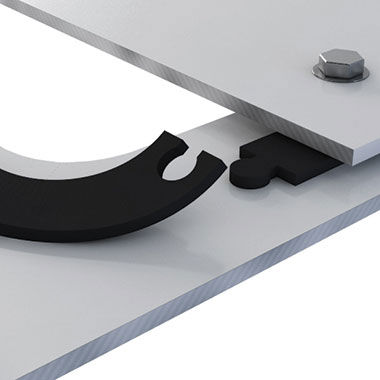

Sealing with profiles

Sealing with gaskets

85+ years of experience with solutions that seal, absorb and protect

Part of 100.000 wind turbines globally

Production in four countries – Denmark, China, Poland, and Italy

A broad range of gaskets made from all types of materials. Our gaskets provide the optimal seal in preventing water, salt, sand, and dust from entering the wind turbine.

Seal efficiently using a standard or customized sealing profile with or without joints. DAFA offers several kinds of profiles, such as edge profiles and extruded EPDM rubber profiles.

DAFA offers you a variety of sealing strips to seal essential components in all wind turbine parts. DAFA’s sealing strips are produced in a variety of materials, such as cellular rubber, solid rubber, PVC, PUR, or PE.

DAFA RotaSeal is designed for rotating parts in the wind turbine and prevents salt, sand, water, and dust from entering vital parts.

DAFA's platform sealings efficiently close the gap between the tower and the platform and are available in both rubber and foam.

DAFA can perform testing in its own climate chamber. Our test center allows us to perform aging tests – subjecting products to harsh climate impacts from heat, cold, UV light and moisture.

Receive advice and guidance on your company’s sealing, absorption or protection needs.

Fill in the form and be contacted by one of our local experts who will help you further or answer the questions you may have.

The engineers in DAFA’s innovation departments are your partners for custom solutions. Their technological insights are key, and we base our advice on the latest technologies and market trends.

Our advanced test center allows us to simulate the most commonly used and recognized national and international standards.

DAFA develops quality products in ultra-modern production facilities using the latest technology.

Based on decades of experience in solving our customers’ challenges, we offer expert advice across many sectors and applications.