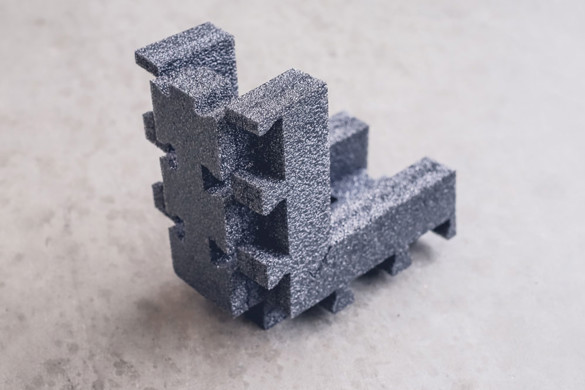

FIPFG - Formed In Place Foamed Gaskets

DAFA's FIPFG technology makes it possible to produce gaskets and make them adhere to a component without manually handling them.

DAFA partners with companies that develop and manufacture products for the Health and Medical industry

We partner with companies that develop and manufacture products to assist and provide relief for people with illnesses and other conditions, such as wound and stoma care.

We also work with companies that produce diagnostic and therapeutic equipment and devices, and materials for masks, visors and other protective equipment. Customers from this sector have strict requirements and high expectations for the final product. We offer materials that comply with the standards imposed by the final recipient.

Great flexibility and an individual approach allow us to solve technological problems the customer is facing, drawing on our extensive production equipment. DAFA offers mass market products as well as more specialized products used in the industrial health and safety segment.

Materials based on:

Products are available in the following forms:

85+ years of experience with solutions that seal, absorb and protect

Strong innovation team

Production in four countries – Denmark, China, Poland, and Italy

Receive advice and guidance on your company’s sealing, absorption or protection needs.

Fill in the form and be contacted by one of our local experts who will help you further or answer the questions you may have

DAFA can perform testing in its own climate chamber. Our test center allows us to perform aging tests – subjecting products to harsh climate impacts from heat, cold, UV light and moisture.

DAFA's FIPFG technology makes it possible to produce gaskets and make them adhere to a component without manually handling them.

DAFA develops, manufactures and supplies custom packaging solutions providing effective protection.

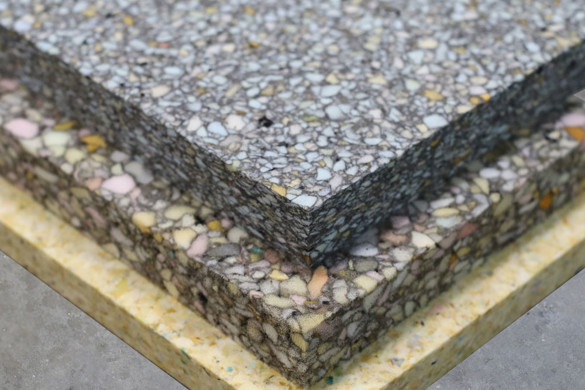

Used for sealing, dampening or protection in a wide range of applications.

DAFA’s edge protection profiles and extruded rubber profiles are used for edge protection and sealing.

DAFA Sound is a complete system for industrial vibration and sound dampening.

DAFA offers a wide range of gaskets made from many types of materials.

The engineers in DAFA’s innovation departments are your partners for custom solutions. Their technological insights are key, and we base our advice on the latest technologies and market trends.

Our advanced test center allows us to simulate the most commonly used and recognized national and international standards.

DAFA develops quality products in ultra-modern production facilities using the latest technology.

Based on decades of experience in solving our customers’ challenges, we offer expert advice across many sectors and applications.